|

| Our Engineering and

Manufacturing departments are at the core of Alexis Fire

Equipment. The process of building a customized truck

starts with customer expectations and ends with customer

satisfaction. All aspects of manufacturing processes are

ultimately driven by and for the customer. How a task

is accomplished is the part controlled by Alexis Fire

Equipment. We thrive on innovation and producing apparatus

that not only exceeds expectations, but pushes the envelope

of conventional fire trucks. What you might have thought

was impossible in a truck can be brought to life with

our team of extraordinary engineers and skilled craftsmen. |

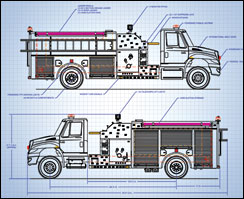

Cad Design

Two-dimensional blueprint of preliminary

truck body assures exact dimensions and maps general design.

|

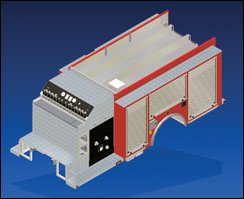

Solid Modeling

Three-dimensional drawings simulate

a virtual model shop and offer a greater definition of

compartment utilization. |

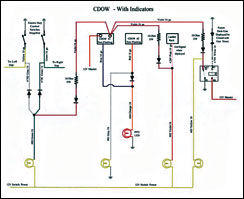

As-Built Wiring Diagrams

Customer-specific exact wiring

diagrams come standard with your Alexis truck and provide

ease of electrical diagnostics. |

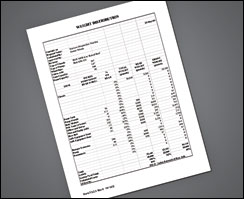

Loading Diagrams

Weight calculations insure intended

loads match correct chassis gross vehicle weight rating

during pre-planning stage. |

|

|

Body Subframe

A fully-welded steel subframe supports

our 3/16" thick aluminum body and allows for heavy-duty

outrigger supports under each compartment floor. A round

rubber body cushion is used to separate the steel outriggers

and aluminum angle which provide our customers with the

strongest truck body possible and the assurance that the

dissimilar metals will be separated to protect against

electrolysis. We also provide a bonded rubber surface

on the top of the subframe to protect from chaffing against

the poly water tank. |

Electrical Panel

Service and maintenance is streamlined

with color, function and number code utilizing heat resistant

wiring, as well as printed circuit boards and automatic

reset circuit breakers. The connections are made through

a duetsch mechanical type connector which allows for the

best seal possible to protect against the elements. We

also now offer your department the option to utilize multiplex

electrical systems. |

|

|

|

|

OMAX

50,000 PSI JetMachining Center

Alexis utilizes computer technology

and cutting-edge machines to provide optimal results.

Along with our plasma cutting machine uses high definition

plasma technology to ensure high quality results when

cutting parts, we also offer one of the fastest and most

precise abrasive waterjet cutting services in the industry

with our Omax 50,000 PSI JetMachining Center. Waterjet

machining is a computerized technology that will cut virtually

any material into any complex two-dimensional shape. Computerized

motion control provides accurate and reproducible results

efficiently throughout a wide range of materials and thicknesses

while generating a smooth edge and finish. We are able

to provide five different edge qualities, ranging from

a fast cut for material separation, to a slow speed for

a superior finished look, minimal burr, and no slag. Material

waste and overall costs are reduced by optimal part positioning

and nesting. Waterjet cutting is a clean process that

does not result in tool path heating, distortion, or residual

stress int he cut material. No heat is used so the molecular

structure of the material remains unchanged. |

|

|

|

|

On-Site

Body Painting

Our apparatus bodies are painted

the Alexis premises using PPG high-gloss finish coatings.

Two coats of paint and three coats of primer for ultimate

durability and quality. The compartments can be finished

in either a natural Aluminum or Zolatone coating. Our

trucks are prepped, the paint color of your choice is

mixed, and the paint is applied to produce the finished,

painted product. |